In complex implant restorations, material selection is one of the most decisive factors for success. The choice of zirconia, titanium, or emerging digital materials directly influences restoration longevity, clinical stability, and patient satisfaction.

Key considerations include:

As an overseas dental lab, Raytops ensures these standards by combining certified sourcing, strict quality control, and digital workflows. This collaborative approach allows clinics to select the right material confidently, balancing predictable outcomes with cost efficiency.

Selecting materials for complex implant restorations requires balancing biological safety, mechanical stability, and aesthetic expectations. Biocompatibility ensures integration with soft and hard tissue, durability determines whether the restoration withstands years of chewing force, and color matching influences how patients perceive treatment outcomes. From our perspective as an overseas dental lab, clients consistently prioritize these three dimensions when evaluating which material to use in advanced cases.

implant-material-selection-factors

Biocompatible materials such as titanium and high-translucent zirconia are proven to integrate well with bone and surrounding tissue. Lack of compatibility can trigger inflammation, prolonged healing, or even implant failure.

Restorations must handle years of chewing cycles and varied dietary forces. Materials with low wear resistance can fracture or cause opposing tooth damage.

Even in complex implant cases, patient satisfaction often depends on appearance. Modern zirconia blocks and advanced staining techniques allow closer shade matching with adjacent teeth.

When clients assess biocompatibility, durability, and aesthetics together, they gain a more balanced view of material performance. As an overseas dental lab, we often see clinics weigh these factors differently depending on patient expectations, but ignoring any one dimension typically leads to higher remake risk or reduced trust. which align with what labs and clinics face in daily decision making.

Different materials affect implant restorations by determining strength, longevity, and adaptability to complex anatomical cases. Zirconia and titanium dominate high-strength applications, porcelain-fused-to-metal (PFM) remains reliable for full-arch frameworks, and 3D-printed polymers and resins are now enabling highly customized precision fits. Each choice reflects a balance between mechanical properties, aesthetics, and workflow efficiency.

implant-materials-performance-comparison

Zirconia and titanium are both trusted in complex implant scenarios, but they serve different roles.

| Property | Zirconia | Titanium |

|---|---|---|

| Strength | High compressive strength, rigid | High tensile strength, flexible |

| Biocompatibility | Excellent with soft tissue aesthetics | Gold standard for osseointegration |

| Aesthetic quality | Tooth-colored, natural look | Metallic, requires veneering |

| Application | Suprastructures, visible restorations | Implants, abutments, load-bearing zones |

| Clinics often pair titanium for implant fixtures with zirconia for visible restorations, leveraging both benefits. |

PFM remains a mainstay in cases requiring durability across multiple units.

3D printing has reshaped complex case handling by allowing customized design and faster prototyping.

Labs and clinics that combine zirconia, titanium, PFM, and 3D-printed solutions can tailor their approach to each case’s mechanical and aesthetic demands. External comparisons such as NCBI’s review on implant material performance reinforce how different materials complement rather than replace one another in advanced cases.

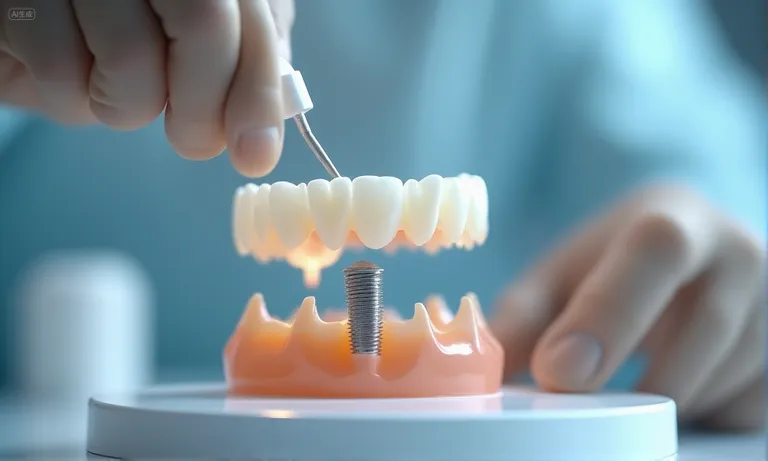

Material compatibility is critical because mismatched surfaces, coatings, or alloys can disrupt osseointegration, extend healing time, and lead to premature implant failures. When the implant fixture, abutment, and restoration material work in harmony, the result is predictable stability. But when compatibility is overlooked, both clinical outcomes and patient trust suffer.

Image

ALT: implant-material-compatibility-check

Prompt: A highly realistic, ultra-detailed, professional-quality photo captured in a clean, well-lit environment. Materials must be photorealistic, and rendered with DSLR-level clarity. Lighting should be soft daylight or studio white light, avoiding cold or bluish clinical tones. A close-up of a dental technician fitting a zirconia abutment onto a titanium implant placed in a bone model, checking compatibility and stability at the interface.

When materials are compatible, the bone forms a strong interface around the implant surface and healing progresses normally.

Mismatched components increase mechanical and biological risks.

Even with the right combination, quality variation between material batches can undermine outcomes.

Ignoring compatibility often means higher costs and more remakes later. From our collaborations as an overseas dental lab, we’ve seen how clinics that standardize implant–abutment–restoration systems enjoy smoother workflows and fewer complications. A helpful resource is the Journal of Prosthodontics study on implant component compatibility, which highlights how mismatches directly impact clinical outcomes.

Raytops ensures high-quality material selection by combining strict sourcing controls, advanced material integration, and a fully digital workflow. This structured approach minimizes remake risks and gives overseas partners confidence that restorations will meet both clinical and aesthetic expectations without compromise.

raytops-dental-lab-material-quality-control

Raytops collaborates only with suppliers that provide certified zirconia, titanium, and alloy products meeting ISO and FDA standards.

Different cases demand different material combinations, and Raytops adapts by integrating them into custom workflows.

Digital workflows reduce human error and create predictable outcomes.

Raytops’ process shows how an overseas dental lab can use discipline and digital precision to reduce remake rates and build trust with long-term clients. A reference such as DE’s Business Lab: Digital workflows for maximum efficiency (Dental Economics) reflects the same trend: when labs embed quality checks and digital systems, results improve across the board.

Material selection directly affects the overall cost of complex implant restorations, not only in upfront pricing but also in long-term maintenance and remake risks. Choosing the right material is less about finding the cheapest option and more about balancing performance, patient satisfaction, and financial sustainability.

Image

ALT: implant-materials-cost-comparison

Prompt: A highly realistic, ultra-detailed, professional-quality photo captured in a clean, well-lit environment. Materials must be photorealistic, and rendered with DSLR-level clarity. Lighting should be soft daylight or studio white light, avoiding cold or bluish clinical tones. A dental procurement manager reviewing cost sheets on a desk with samples of zirconia discs, titanium abutments, and a PFM framework arranged side by side.

Each material carries unique cost implications for clinics and labs.

Clinics and labs often evaluate materials based on value rather than lowest cost.

| Material | Initial Cost | Long-Term Risk | Best Use Case |

|---|---|---|---|

| Zirconia | High | Low (few remakes) | Visible restorations, complex bridges |

| Titanium | Moderate | Very low | Implants, abutments, load-bearing areas |

| PFM | Moderate | Moderate to high | Full-arch restorations with lower esthetic demand |

| 3D-printed | Low | Variable | Temporary restorations, try-ins, surgical guides |

| This balance helps procurement teams optimize budgets without sacrificing patient outcomes. |

Higher-quality materials often save costs by reducing remakes, improving patient satisfaction, and shortening chairside time.

Balancing material costs is ultimately about total case value, not just price tags. Industry resources like the cost-effectiveness analysis of implant-retained prostheses (implant-retained overdentures) confirm that long-term outcomes often justify initial investment in higher-grade materials.

Choosing the right material for complex implant restorations is not just a technical step—it is a strategic decision that shapes long-term clinical success, patient satisfaction, and cost efficiency. Biocompatibility, durability, aesthetics, compatibility, and value all play interconnected roles in ensuring predictable outcomes.

From our perspective as an overseas dental lab, we have seen that clients who prioritize both material quality and workflow integration face fewer remakes, smoother collaboration, and stronger patient trust. By combining certified sourcing, digital workflows, and careful cost-value evaluation, labs and clinics together can achieve restorations that are not only functional but lasting investments.