Collaboration and digital workflow compatibility are central to achieving predictable outcomes in dental implant cases. Procurement teams seeking reliable partners must prioritize labs that combine seamless communication with robust digital tools, ensuring accuracy, faster case handling, and long-term consistency.

Key benchmarks include:

By focusing on these criteria, procurement managers reduce risks, streamline cross-border collaboration, and establish enduring trust with overseas dental labs. The result is greater efficiency, lower remake rates, and reliable implant restorations that meet global expectations.

Smooth collaboration and strong digital workflow compatibility are essential in dental implant cases because they directly affect treatment accuracy, turnaround time, and patient satisfaction. When clinics and labs align on processes and digital standards, remakes decrease, communication becomes faster, and restorations fit more predictably. Procurement teams evaluating implant labs should place collaboration and digital integration at the top of their criteria.

dental-implant-collaboration-digital-workflow

When labs and clinics lack structured collaboration, small misalignments often escalate into costly delays. Missing case details, unclear instructions, or delayed responses may force multiple iterations, stretching production timelines and undermining patient trust. A procurement team should recognize that poor coordination typically translates into higher chairside adjustments and greater logistical complexity.

Digital systems allow labs and clinics to share case files, scans, and designs without the bottlenecks of manual processes. When labs accept and natively process common formats such as STL, the risk of data corruption or interpretation errors decreases. Studies highlight that standardized digital workflows reduce remake rates and ensure consistent quality outcomes.

Procurement teams should evaluate whether a lab demonstrates both collaboration readiness and technical compatibility. This includes clear case intake processes, responsive support staff, and proven experience with multiple implant systems. A lab that consistently invests in digital upgrades and collaborative tools signals long-term reliability, making it a more sustainable partner for practices and DSOs.

File compatibility and secure data sharing are critical in dental implant workflows because every stage—from intraoral scanning to final restoration—depends on accurate, accessible, and protected digital files. Clinics and labs that align on formats, version control, and data security avoid costly remakes, reduce confusion, and maintain compliance with patient privacy regulations.

dental-implant-digital-file-compatibility

The STL (stereolithography) format has become the universal language for dental CAD/CAM because it ensures accuracy across scanners, design software, and milling machines. Its compatibility allows clinics to share digital impressions with almost any lab, reducing the risk of misinterpretation. While proprietary formats exist, STL’s wide acceptance makes it the most reliable foundation for implant collaboration.

Version mix-ups are a leading cause of delays in implant cases. Procurement teams and labs can minimize errors by following structured version control:

Beyond compatibility, secure transfer is a legal and operational requirement. Labs and clinics should evaluate:

Clear and consistent communication is essential to prevent delays, remakes, and misinterpretations in implant workflows. When clinics and labs adopt structured communication practices—dedicated platforms, feedback loops, and defined response protocols—they reduce errors and create predictable collaboration pathways. This not only supports clinical accuracy but also builds long-term trust in procurement partnerships.

dental-implant-collaboration-communication

Dedicated communication platforms integrate file sharing, case notes, and instant messaging into a single workflow. Tools like 3Shape Communicate allow dentists to send scans, receive feedback, and track case status without relying on scattered emails. By centralizing collaboration, these platforms reduce information loss and ensure all parties have real-time access to case updates.

Effective collaboration relies on continuous feedback rather than one-way communication. Procurement teams should prioritize labs that:

Even the most advanced tools fail if there is no accountability. Clear communication protocols include:

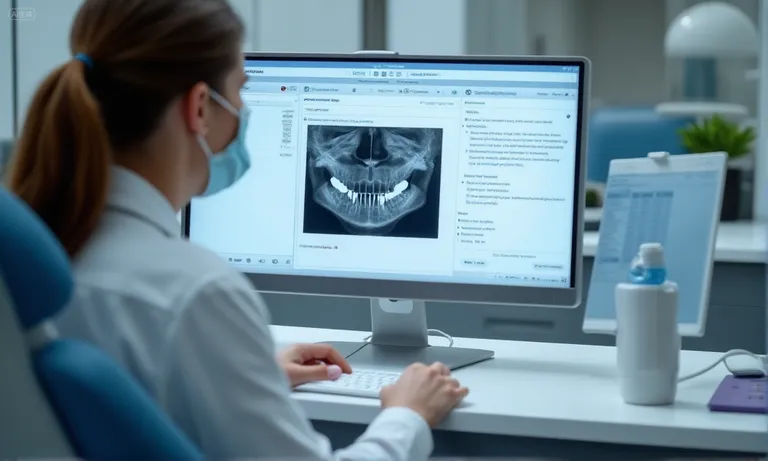

Assessing a dental lab’s digital capabilities is essential to ensure implant restorations are precise, predictable, and efficiently delivered. Procurement teams should focus on whether the lab uses advanced CAD/CAM systems, integrates 3D printing for guides and models, and supports virtual planning tools that enhance surgical accuracy. A lab’s technology stack is a direct reflection of its ability to handle complex cases and collaborate seamlessly across digital workflows.

dental-lab-digital-tools-evaluation

CAD/CAM technology is the backbone of digital implant workflows. Advanced systems allow for highly accurate restorations by translating scans into precise milling or printing instructions. Labs with established CAD/CAM expertise minimize human error and deliver consistent quality, which reduces remakes and enhances clinical outcomes.

3D printing has become indispensable in implant dentistry because of its speed and flexibility. Labs use 3D printing to create surgical guides, provisional restorations, and diagnostic models. Compared to traditional processes, additive manufacturing allows faster turnaround, improved fit, and lower production costs, particularly for custom or complex implant cases.

Virtual planning platforms integrate radiographic data with intraoral scans, allowing clinicians and labs to simulate implant placement before surgery. By visualizing bone density, angulation, and prosthetic design, these tools reduce the risk of surgical surprises and improve prosthetic-driven implant planning. Popular tools like coDiagnostiX enable labs to actively participate in planning, ensuring restorations align with surgical realities.

Managing turnaround time in implant restorations is a balancing act between speed and quality. Procurement teams should evaluate how a lab structures its production schedules, handles urgent cases, and maintains reliability in global logistics. Consistent delivery builds confidence in long-term partnerships, while a lack of coordination risks patient dissatisfaction and treatment delays.

dental-implant-turnaround-time-management

Most implant restorations follow defined timeframes depending on case complexity:

These benchmarks help clinics align patient scheduling with lab production capacity, reducing chairside delays. Some industry references, such as the National Dentex turnaround calendar, list implant restorations at around 10 working days, which matches common clinical expectations.

Urgent needs—such as last-minute surgical changes or fractured temporaries—require labs with defined rush capabilities. Effective features include:

Clinics rely on these systems to meet patient needs promptly without sacrificing accuracy.

Reliability matters as much as speed. Procurement teams should assess:

Consistent delivery reflects operational maturity and scalability—key for growing implant volumes.

Long-term collaboration in implant dentistry requires more than just meeting today’s case requirements. A reliable lab must continuously refine its digital workflows—through staff training, cross-disciplinary collaboration, and technology adoption—to remain a dependable partner as clinical expectations evolve. Procurement teams that evaluate a lab’s improvement culture reduce the risk of workflow stagnation and ensure smoother integration in the future.

dental-lab-staff-digital-training

Dental technology evolves quickly, and labs that provide structured training ensure technicians stay updated on new CAD/CAM tools, material science, and implant system integrations. For example, the NADL Learner Community virtual training catalog offers numerous online courses that keep lab teams aligned with digital workflow advances and industry standards.

Cross-training encourages technicians to understand clinical workflows and clinicians to better grasp lab processes. This shared knowledge improves communication and reduces costly missteps, such as unclear scan data or misinterpreted margin designs. Labs that promote joint webinars, digital case reviews, or in-person training foster a culture of collaboration that benefits both sides.

A lab’s willingness to invest in updated scanners, milling machines, and software upgrades directly impacts case predictability. For instance, Dentistry.co.uk reported that 3Shape Dental System 2024 includes AI-driven design automation, faster case management, and enhanced workflow integration—showing how software improvements can dramatically elevate lab efficiency and collaboration.

Labs that continuously invest in people and tools build resilience against industry changes. For procurement teams, this signals a partner capable of long-term alignment, not just a transactional vendor.

Evaluating collaboration and digital workflow compatibility in dental implant cases is essential for building trust and ensuring predictable outcomes. Labs that invest in training, adopt new technologies, and maintain transparent communication provide greater reliability in complex restorative work. For procurement teams, the value lies not only in precision but also in the ability to scale, adapt, and support clinicians effectively. By choosing an overseas dental lab committed to continuous improvement, clinics can secure a long-term partner that reduces risk, streamlines digital integration, and consistently delivers restorations that meet global standards.