Manual variability, unclear margins, and inconsistent outcomes have long limited the precision of PFM crown fabrication.

These challenges lead to time-consuming adjustments, remakes, and patient dissatisfaction that eat into clinical efficiency.

CAD/CAM integration transforms Hi-Noble PFM workflows by delivering digital precision, reproducible fit, and cost-efficient crown production from lab to chairside.

CAD/CAM integration improves precision in Hi-Noble PFM fabrication by replacing manual steps with digital scanning, design, and milling. This enhances fit accuracy, margin integrity, and material efficiency, reducing remakes and chairside adjustments while ensuring consistent crown performance and esthetics.

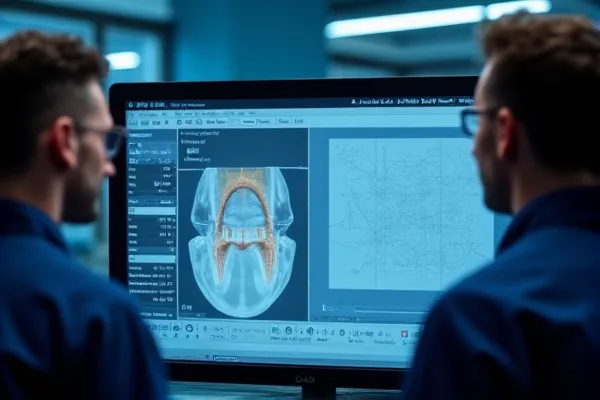

CAD/CAM (Computer-Aided Design and Computer-Aided Manufacturing) enables dental labs to design and produce Hi-Noble PFM crowns with exceptional precision and repeatability. By replacing manual steps with digital workflows, CAD/CAM significantly improves framework accuracy, consistency, and production speed—key factors for clinics seeking reliable crown quality.

Dental-CAD-CAM-Hi-Noble-Workflow

The CAD/CAM system includes a digital scanner, CAD software for design, and CAM equipment (e.g., milling units or 3D printers).

This integration ensures a seamless transition from impression to final framework.

Most modern labs use a hybrid workflow where CAD/CAM replaces manual modeling but retains hand-layered ceramic artistry.

This balance of automation and craftsmanship is ideal for Hi-Noble PFM cases, where both fit and esthetics matter.

Precision is critical to reduce chairside adjustment and ensure crown longevity.

For clinics, this means fewer remakes, faster delivery, and more predictable outcomes.

✅ CAD/CAM improves consistency and precision in Hi-Noble PFM fabrication – TRUE

Its digital workflow eliminates many sources of human error and ensures standardized outcomes.

❌ Manual fabrication always offers better fit and control than CAD/CAM – FALSE

Digital tools now exceed manual precision in many aspects of crown production, especially for margins and internal adaptation.

Design accuracy is critical to the long-term success of Hi-Noble PFM restorations. CAD/CAM technology significantly improves fit, contour, and marginal integrity by removing subjectivity from the design process. The result is a crown that requires fewer adjustments and offers better clinical outcomes from the first try-in.

CAD-CAM-Accuracy-Hi-Noble-PFM-Design

Accurate scanning ensures precise data for digital design.

The better the data at the start, the more precise the final crown fit.

CAD software translates raw scans into clinically optimized restorations.

CAD tools enhance design reproducibility while preserving esthetics and function.

Manual design can introduce variability due to hand skills or technician fatigue.

This creates more predictable results—especially in large-volume clinics or DSOs.

✅ CAD/CAM enhances design accuracy in Hi-Noble PFM crowns – TRUE

It reduces subjectivity, improves fit precision, and minimizes adjustment time during placement.

❌ Digital design increases error risk compared to manual modeling – FALSE

Modern CAD tools have error-prevention features that improve consistency and minimize human oversight.

Material efficiency plays a major role in the cost and sustainability of Hi-Noble PFM crown production. CAD/CAM technology helps dental labs minimize alloy waste, optimize substructure design, and maintain consistent output—all while supporting long-term profitability and inventory control.

Hi-Noble-Alloy-Usage-CAD-CAM-Workflow

Digital tools allow substructures to be designed with just enough thickness and support.

Smarter design means less alloy needed per crown—without compromising strength.

Material savings aren’t just about usage—they’re about what gets lost in the process.

Better planning upstream avoids material loss downstream.

Hi-Noble PFM crowns require consistent quality across batches to maintain predictable fit and finish.

Consistency in material handling leads to better outcomes—and lower rejection rates.

CAD/CAM systems maximize the utility of every gram of Hi-Noble alloy by ensuring precise usage, minimal waste, and consistent production standards across batches.

Integrating CAD/CAM into PFM crown workflows is not just a technical upgrade—it’s a strategic decision. Labs using digital tools gain speed, precision, and consistency across every case. For clinics, this means fewer delays, fewer remakes, and more predictable treatment outcomes.

CAD-CAM-Benefits-Dental-Lab-Hi-Noble

Digital workflows compress time without cutting corners.

More crowns, less time—without losing control over margins or anatomy.

Automation lowers both variable and fixed costs in lab operations.

For high-volume labs and growing clinics, automation unlocks scale without burnout.

Consistency builds trust between lab and clinic.

This means fewer chairside surprises and a stronger reputation for your restorations.

When properly integrated, CAD/CAM boosts lab output, lowers costs, and builds consistency—all without sacrificing quality.

Download our CAD/CAM integration roadmap to learn how labs and clinics can implement scalable digital workflows for Hi-Noble PFM crowns.

The precision offered by CAD/CAM integration directly affects both the initial fit and long-term durability of Hi-Noble PFM crowns. Consistent marginal seal, accurate occlusion, and reduced micro-gaps lead to fewer adjustments, lower biological risk, and restorations that perform reliably over time.

Hi-Noble-PFM-Crown-Fit-Longevity-CAD-CAM

Margins define the success of a crown, both functionally and biologically.

Perfect margins protect underlying tooth structure and reduce post-cementation sensitivity.

Better fit means less wear and lower mechanical stress over time.

Precision isn’t just a lab advantage—it protects restorations for years in function.

Chairside efficiency depends on getting things right the first time.

This saves time, increases patient confidence, and reduces follow-up visits.

✅ CAD/CAM precision improves both fit and long-term performance of Hi-Noble PFM crowns – TRUE

Better fit reduces mechanical wear, patient sensitivity, and clinical chair time over the crown’s lifespan.

❌ Digital crowns need more chairside adjustments than manually made ones – FALSE

Properly calibrated CAD/CAM workflows consistently outperform manual techniques in marginal and occlusal accuracy.

Even with advanced CAD/CAM systems, consistent quality requires disciplined workflows and skilled technicians. Precision is not only about tools—it’s about how labs use them. From design protocol to quality checks, labs play a central role in delivering high-performance Hi-Noble PFM restorations.

Dental-Lab-CAD-CAM-Precision-Workflow

Digital systems streamline processes from scan intake to final casting.

A structured digital process allows technicians to focus on fine-tuning rather than firefighting.

Maintaining accuracy isn’t just about getting it right—it’s about checking that it stays right.

Labs with systematic QC catch issues before the crown ever leaves the building.

Technology only delivers value when used correctly—and confidently.

Labs that invest in ongoing training maintain their edge in precision and reliability.

Consistent results with Hi-Noble PFM crowns depend on more than the right software—they require tight protocols, strong quality control, and a team that evolves with the technology.

Digital collaboration between clinics and labs enhances more than just crown design—it improves timelines, cost-efficiency, and patient satisfaction. For dental practices, integrating with CAD/CAM-capable labs unlocks practical, measurable advantages throughout the restorative workflow.

Dental-Clinic-CAD-CAM-Benefits-Hi-Noble

Faster production helps clinics plan with confidence.

Timely delivery reduces patient wait and frees up chair time for new cases.

Patients notice when treatment flows smoothly.

Clinics that consistently deliver quality on schedule build lasting trust with patients.

Digital cases reduce hidden overheads.

Efficiency is profitability—and CAD/CAM helps clinics stay ahead.

Integrating with CAD/CAM-enabled labs gives clinics real, daily benefits: shorter turnaround, smoother delivery, and fewer surprises.

Talk to our technical team to explore how your practice can optimize crown sourcing and scheduling with CAD/CAM support.

The integration of CAD/CAM in Hi-Noble PFM fabrication marks a pivotal shift toward precision, predictability, and efficiency. From accurate scanning to optimized substructure design, digital workflows empower both labs and clinics to reduce errors, save time, and enhance crown longevity across case types.

To experience CAD/CAM-backed Hi-Noble crown workflows, connect with Raytops Dental Lab and discover how precision meets consistency in every case.