Digital implant workflows have transformed how clinicians plan and deliver implant treatments. By replacing analog steps with scanning, simulation, and guide fabrication, clinics can achieve higher precision, shorter timelines, and improved patient satisfaction—while enabling seamless collaboration with labs and digital planning centers.

A digital workflow in implant dentistry replaces physical steps with digital tools—from intraoral scans to 3D-printed surgical guides—improving precision, efficiency, and outcomes. Raytops is a over 12 years dental lab specializing in high-precision implant prosthetics. We are proud to be certified, ISO and support clinics integrating digital workflows.

Based on our observations working closely with many clinics, adopting a digital workflow marks a significant evolution in implant dentistry. We see it as a tech-driven approach that seamlessly connects all stages of care – from that crucial first scan to the final restoration – enabling smoother collaboration between your clinical team and our lab.

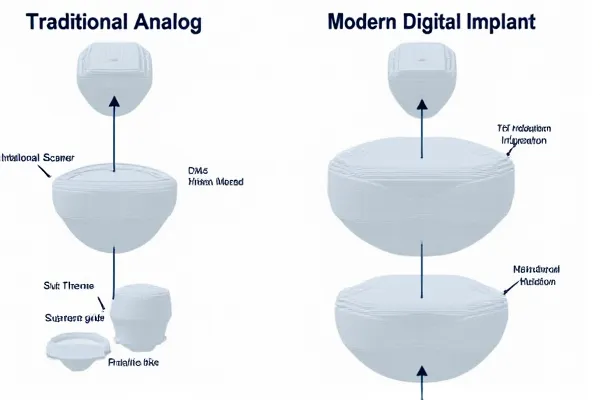

Digital vs. analog implant steps

Digital workflows diverge from traditional protocols in method, efficiency, and reproducibility.

Understanding each link in the chain ensures workflow consistency.

Digital systems offer improvements across clinical, technical, and experiential domains.

A hybrid model may be ideal for clinics still transitioning.

✅ Digital workflows enhance every stage of implant therapy – TRUE

Explanation: Accuracy, speed, and reproducibility all improve with full digitalization.

❌ Analog workflows are equally efficient for modern implant cases – FALSE

Explanation: Analog lacks digital precision and slows clinical decisions.

From our perspective at the lab, the initial digital impression is where the accuracy of the entire workflow begins. A successful digital workflow begins with a clean, precise intraoral scan, supported by a well-positioned scanbody. This foundation determines the accuracy of every step thereafter, impacting everything from guide fit to final restoration.

Intraoral scan with scanbody

From our perspective at the lab, the accuracy of your initial intraoral scan is fundamental to the entire digital process. An accurate digital impression depends on correct scanbody use. To help us ensure the best possible fit and outcome for your case, we’ve found the most successful scans consistently demonstrate attention to these points:

Tissue detail determines crown fit and emergence contour.

Scan quality determines prosthetic accuracy.

| Error Type | Cause | Prevention |

|---|---|---|

| Data voids | Incomplete scan paths | Multiple passes from different angles |

| File mismatch | Wrong scanbody model used | Cross-check with lab before scanning |

| Distortion | Moisture on lens or movement | Dry field + patient stabilization |

Different scanning strategies are needed depending on the clinical case.

✅ Digital impression quality drives the entire implant planning chain – TRUE

Explanation: Errors here compound in guide design, placement, and restoration.

❌ Any scan can be cleaned up digitally, regardless of how it’s captured – FALSE

Explanation: Poor raw data leads to misfits even with post-processing.

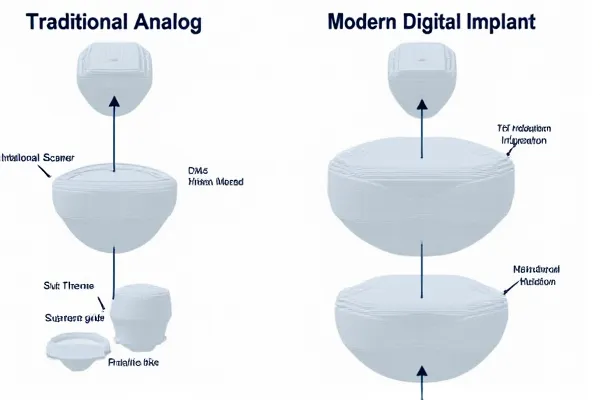

Digital planning converts raw scan and CBCT data into a surgical strategy. This is where your clinical expertise meets digital precision, and it’s the crucial step where our lab collaboration truly begins. Digital planning allows clinicians to virtually place implants in ideal positions before a drill ever touches bone. We then utilize this plan to ensure the prosthetic outcome aligns with your vision and the technical requirements for guide fabrication.

Implant planning software

Overlaying anatomical data with scan geometry is the core of guided planning.

Ideal position balances esthetics and biomechanical stability.

Virtual planning prevents access and torque issues later.

Multi-role coordination ensures accuracy.

✅ Digital planning enables safe, prosthetically-driven surgery – TRUE

Explanation: It minimizes surprises and increases placement confidence.

❌ Planning software is optional if surgical skills are strong – FALSE

Explanation: Even expert surgeons benefit from guided precision and visualization.

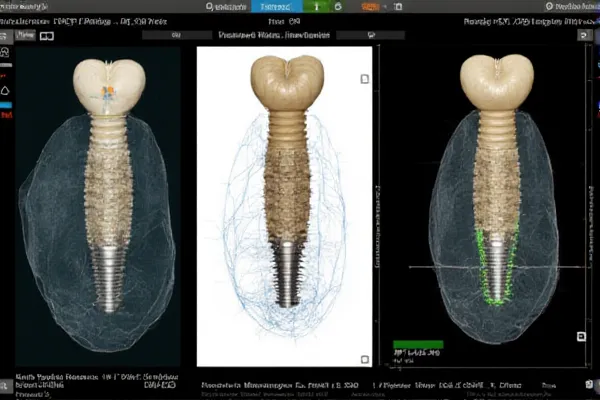

Once the implant plan is approved, it’s translated into a physical guide that transfers the digital plan to the clinical setting with precise angulation, depth, and sleeve compatibility. For us at the lab, the surgical guide is the physical manifestation of your meticulous digital plan, and its accurate fabrication is paramount to translating virtual precision into surgical reality.

Surgical guide design in CAD

Each guide type suits different clinical demands.

| Guide Type | Description | Ideal Use Case |

|---|---|---|

| Fully Guided | Controls drilling, depth, and implant angle | Precise single/multi-unit |

| Pilot Guide | Controls only initial pilot drill | Cases with good visibility |

The sleeve acts as the control point for angulation and depth.

Guide quality depends on print resolution and material.

Every guide should be verified chairside. Additionally, at our lab, we implement rigorous internal QA and fit testing before the guide leaves our facility.

At our lab, rigorous internal QA is a critical step before the guide leaves our facility. This includes:

✅ Accurate guide design translates digital precision into surgical success – TRUE

Explanation: The guide is the physical expression of your planning accuracy.

❌ Surgical guides are optional in digital workflows – FALSE

Explanation: Skipping a guide negates most of the digital planning benefits.

Digital systems not only streamline processes—they also reduce errors and improve the predictability of surgical and restorative results. From our observation receiving cases and seeing the final restorations, the impact of a digital workflow on clinical outcomes is clear and consistently positive.

Surgery with printed guide in place

Studies confirm high alignment between virtual and actual placement.

Deviations typically <1mm at apex.

Superior in narrow ridges or esthetic zones.

Our experience at the lab bench, analyzing post-operative scans, consistently confirms the high degree of accuracy seen in digitally planned and guided cases. While clinical studies quantify this, we see that deviations are typically minimal, often less than 1mm at the apex. This precision is particularly noticeable in challenging cases like narrow ridges or esthetic zones where achieving predictable placement with analog methods can be difficult.

Digital prep minimizes in-chair improvisation.

Digital workflows reduce intra- and post-op surprises.

Digital data allows pre-planned provisionalization.

✅ Digital workflows lead to better accuracy, faster surgery, and fewer complications – TRUE

Explanation: Clinical studies and real-world outcomes support this impact.

❌ Digital workflows only benefit the lab side, not surgery – FALSE

Explanation: Both planning and placement see measurable improvements.

Going digital requires both technical and operational readiness. As a lab partner supporting many clinics through this journey, we understand the significant considerations involved. A clear understanding of investment, training, and ROI is essential before making the transition.

Digital workflow equipment and staff

Hardware and software form the digital backbone.

Technology requires human alignment to succeed.

Your lab must match your digital ecosystem.

Digital workflows offer strong return—but not overnight.

✅ A well-executed digital adoption plan yields lasting efficiency gains – TRUE

Explanation: Most clinics recover costs through time savings and patient acceptance.

❌ Going digital is mostly about having trendy technology – FALSE

Explanation: It’s about clinical accuracy, workflow control, and long-term ROI.

The digital workflow in implant dentistry represents more than just a tech upgrade—it’s a complete transformation of how implants are planned, placed, and restored. With the right training, tools, and lab support, clinics can achieve faster, safer, and more esthetically pleasing outcomes for their patients.

Take the Next Step

Want to integrate a full digital workflow in your practice? Let’s partner to make it happen. We can help you navigate equipment compatibility, support your team’s training from the lab side, and ensure our reliable lab partnership provides the consistent results you need for predictable digital implantology.